Rubber Chopper

Rubber Grinding & Chopping

Low speed. High durability. Faster dissolution.

The Bepex Rubber Chopper reduces bales of synthetic and natural rubber to small particles through a combination of low speed and high torque. The low-speed, high-torque design minimizes heat input while providing the power needed to grind rubber bales to crumbs. The resulting particle size ranges between 0.5-1 inch (1.2-2.5 cm), which speeds dissolution prior to blending and compounding.

Increase Productivity

Reduce the time it takes to dissolve natural or synthetic rubber ahead of compounding or molding lines without sacrificing reliability

Low Speed. High Durability

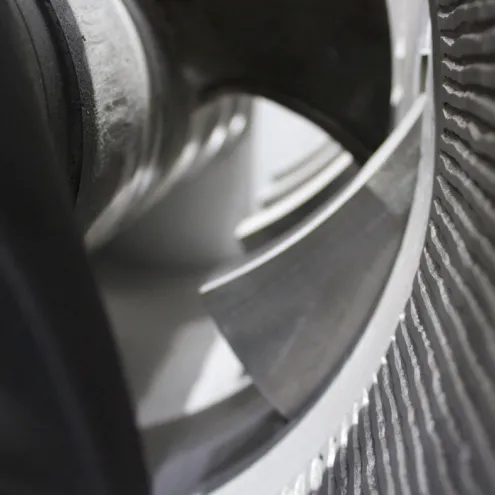

The low-speed operation lessens wear on the rotating assembly while limiting heat generation. That prevents melting prior to dissolution and the excessive wear often seen in high-speed grinding equipment.

Reliable Design

The rugged, heavy-duty design ensures wear life and operation while minimizing unnecessary downtime.

Advantages

Flexible Configurations

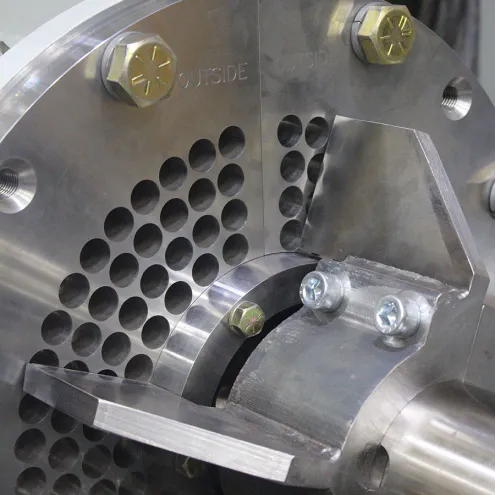

Design options include various orifice plate sizes, cutoff knife speeds, main shaft speeds, and hammer configurations to provide the capability to granulate a wide range of polymers and rubbers.

Consistent Particle Size

Application-specific orifice or spoke plate design and cut-off knife assemblies provide consistent control of product particle size.

Heavy-Duty Design

Heavy-duty design accepts full bales of any polymer. Rugged construction practically eliminates unplanned maintenance and unnecessary downtime.

Adjustable Torque

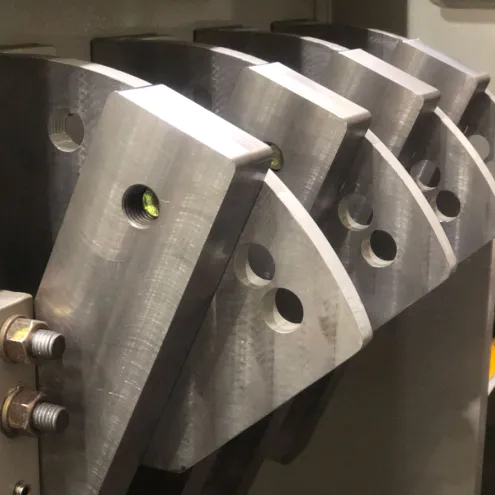

Adjustable internal anvils deliver full control over the amount of energy imparted into your materials. Through external adjustment, you can add or remove restrictions to reduce or increase your resulting grind.

Ram Feeder

Designed for more difficult materials, the optional pneumatic ram feeder provides just the right pressure to force blocks into the grinding zone.

Low speed. Low noise.

The low operating speed provides a more comfortable working environment compared to high-speed, noisy shredders.

How does it work?

Rubber or polymer bales enter the feed hopper, typically by gravity from a feed conveyor or with a pneumatic ram.

The bale lowers onto the rotating shaft equipped with claw-like hammers. These hammers begin cutting through and grabbing the bale, pulling it into the cutting zone.

The shaft begins cutting apart the bales of rubber, breaking them down into more manageable pieces. The claw-hammers run between stationary and adjustable anvils along the body of the Rubber Chopper. These adjustable anvils allow you to control the amount of energy imparted on the bale of rubber.

Depending on the material being processed or the downstream operations, Bepex can provide dosing equipment to add anti-sticking agents such as talc either in the grinding chamber or at the discharge.

The ground rubber continues forward to the discharge where it is forced through an orifice plate. Upon exiting, the extruded rubber is sheared by the cutoff knife assembly, producing a consistently sized granule ranging in size from 1/2 up to 1 ½ inches.

The chopped rubber typically drops by gravity into a tank where it is mixed in a solvent with other materials, dissolved, and sent to molding or compounding.

Tough Rubber Grinder. Built to Last.

The Bepex Rubber Chopper is the original low-speed, high-torque grinder for bales of natural and synthetic rubbers.

Low speed prevents heat build up while high torque generates power to grind bales into crumbs, which speed downstream dissolution.It’s just that easy.

Contact a Bepex process expert to learn more.