All Products

At Bepex, we custom configure and design our products to meet your exact needs for quality, performance and delivery.

With the industry’s broadest range of thermal treatment, separation, size reduction and agglomeration equipment, we can offer options for nearly any material transformation challenge you face.

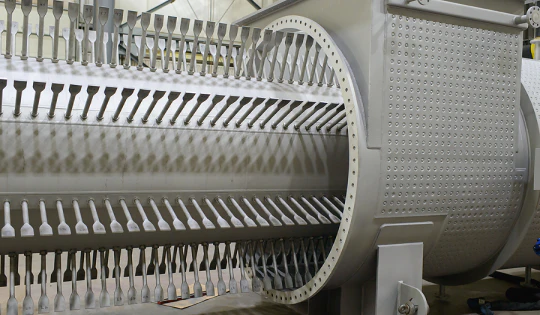

Continuator

Continuous Pressure Cooker

The Continuator allows processors to convert common batch processing applications into continuous operations – increasing throughput, cutting costs, and expanding downstream processing options. The indirect bed technology is used for pressure cooking, vacuum reactions, or long residence time devolatilization.

PCX

State-of-the-Art Drying for High Moisture, Non-Pumpable Materials

The PCX dispersion flash dryer processes high-moisture materials including non-pumpable wet cakes, pastes and slurries into a fine powder or small granules. No extra dilution is required for processing, meaning faster drying, less energy use, and lower emissions.

Fluid Bed Dryer

Stationary Fluid Bed Dryer

The Fluid Bed dryer uses process air to fluidize the bed of solids, providing highly controlled, gentle drying, reacting, cooling, or curing. Its stationary design eliminates moving parts, resulting in a small footprint, less maintenance, and more uptime.

Purge Vessel

Hot Air Hopper Dryer

The Purge Vessel is a long residence time hopper providing near-complete removal of volatile organic compounds from bulk solids. Its proprietary design offers superior material flow and a low-cost option for reducing volatiles from 1-2 percent to low PPM levels.

Thermascrew

Heated Screw Conveyor

The Thermascrew conveys material while providing gentle, uniform heating, cooling, evaporating, or roasting. The slow-rotating rotor protects delicate materials, preserving particle shape and form. Thermascrew is used to convey and heat or cool liquids, slurries, powders, or granules.

S-Press

Industrial Screw Press

The S-Press is designed for mechanical dewatering, juicing, or solvent removal. It squeezes liquid from feeds to lower costs of drying or other downstream processing. Its compact footprint, sanitary design, and easy cleaning make it widely used in food processing.

Solidaire

Thin-Layer Indirect Paddle Dryer

The Solidaire thin layer paddle dryer offers the highest heat transfer coefficient available. Process dry or wet solids, liquids, slurries, cakes or pastes more efficiently, with more control, at lower cost. Solidaire applications include drying, devolatilizing, reacting, cooling, and crystallizing.

TorusDisc

Adjustable Disc Bed Dryer

The TorusDisc dryer is designed for high heat loads and long residence times. The TorusDisc provides maximum heat transfer and complete processing control in a compact footprint, making it ideal for drying, reacting, crystallizing, and heating or cooling processes.

RP Disintegrator

Sanitary Angled Hammer Mill

The RP Disintegrator is designed for grinding, delumping, pureeing, and homogenizing. Its design provides operational versatility including quick cleaning, change overs, and maintenance. It grinds wet and dry materials to produce solid particles, fine purees, or pastes.

Granulator

Coarse Grinding Dry Granulation Mill

The Granulator is designed for precise granulation of dry solids, producing exact-sized, to-spec particles ranging in size from 4-100 mesh at high speeds. Its drop-through design requires little floor space and provides high-capacity milling capabilities in a small footprint.

Extructor

Sanitary Food Pulverizer

The Extructor food-grade grinder reduces the size of large blocks of frozen meats, fruits, or vegetables, or wheels of cheese ahead of downstream cooking. The reduced feed size exposes more surface area to decrease cooking and blending time.

Pulvocron

Air Classifying Mill

The Pulvocron air classifying mill uses high-speed impact and internal size classification to produce fine powders with narrow size distribution. Heat, dry, cool, mill all in one machine. Grind powders to a D50 as fine as 3 μm.

RD Disintegrator

Heavy Duty Hammer Mill

The RD Disintegrator is built for tough jobs like wet and dry grinding, shredding, pulping, and pulverizing. It excels in processing tough-to-grind feeds and features internal tramp material separation to remove unwanted materials, protecting the product and downstream equipment.

RI Disintegrator

Inline Wet Grinder and Delumper

The RI Disintegrator is an inline grinder used to delump pastes, slurries, liquids, resins, and solids held in liquid suspension in order to protect downstream equipment. Easy to install, replacing traditional strainers with the RI reduces clogging, maintenance, and downtime.

Rubber Chopper

Rubber Grinding & Chopping

The Rubber Chopper reduces bales of synthetic and natural rubber to small, less than inch-sized pieces. The low-speed, high-torque design minimizes heat generation while providing massive grinding power. The smaller feed size speeds material dissolution prior to blending and compounding.

Extrud-O-Mix

Low Pressure Extruder

The Extrud-O-Mix bridges the gap between mixing/blending and particle enlargement equipment. It uniformly mixes powders and liquids, producing pastes or consistent, free-flowing pellets or granules. The Extrud-O-Mix combines the mixer, kneader, and extruder into a single unit, simplifying process flow.

FlexTurbulizer

Self-Cleaning Paddle Mixer

The FlexTurbulizer is specifically designed to handle cohesive, sticky materials that traditional mixers can’t. Its flexible, self-cleaning mixing chamber eliminates solids buildup that fouls traditional mixers. The result: less downtime, more consistently rounded particles, and superior granule quality.

Hydramix

Twin-Rotor Paddle Mixer

The Hydramix is designed to mix and hydrate during long residence times without particle degradation. Its self-cleaning design reduces material build up – providing more consistent operation, greater mixing capabilities, reduced maintenance, and support for difficult transitions during reaction processes.

Roll Compactor

High Pressure Briquetting and Granulating System

The Roll Compactor dry presses fine powders or dust into larger granules, briquettes, pellets, or other specialized shapes. The Roll Compactor forms shapes without adding a liquid binder, eliminating the cost and complexity of additional downstream drying processes.

TurboFlex

High Speed Vertical Instant Mixer

The TurboFlex is purpose-built for instant mixing. The self-cleaning, flexible mixing chamber prevents material build-up, making the TurboFlex ideal for hydrating difficult-to-wet powders; coating or surface-treating solids; or producing particles with rapid dispersion requirements.

Turbulizer

High Shear Industrial Paddle Mixer

The Turbulizer is built for near-instantaneous mixing or agglomeration of liquids and solids. Its high-speed rotor with adjustable paddles creates intense turbulence with short residence times to produce dust-free particles ranging in size from fine powders up to 2-3 mm.