PCX

State-of-the-Art Drying for High Moisture, Non-Pumpable Materials

Dispersion Flash Dryer

The Bepex PCX dispersion flash dryer processes high-moisture materials including non-pumpable wet cakes, pastes and slurries into a fine powder or small granules. PCX’ s proprietary design uses less energy, requires less space and is ideal for processing temperature-sensitive or organic materials.

Lower Energy, Emissions and Cost

The PCX takes material in a non-pumpable state. No need to add water just to convey and process. By requiring no additional feed moisture coming into the dryer, the PCX naturally reduces the energy required in drying. Lowering the heat intensity requirement lowers the amount – and expense – of fuel required for drying. It also lowers the resulting emissions.

Smaller Footprint

The PCX’s unique design provides a higher capacity in a smaller footprint. You’ll save both floor space and vertical space without the height of a spray dryer or the immense ducting of a ring dryer.

Protect Sensitive Materials

Material residence time in the dryer is under five seconds. Combined with PCX’s evaporative cooling design and typical one-pass operation, the short residence time protects temperature-sensitive materials while still achieving high evaporation rates.

Advantages

Lower Energy Consumption

By reducing the feed moisture into the dryer, we reduce the energy required in drying. Plus we’ve partnered with upstream mechanical separation companies to deliver utility savings, lowering the overall cost per ton for your value-added product.

Drying without Dilution

The PCX’s proprietary drying technology handles viscous, non-pumpable materials without extra dilution for processing. Stop diluting your solids for pumping just to dry them again and waste water, energy and money.

Heat History Control

The combination of efficient, consistent drying along with evaporative cooling provides absolute control over heat history, ensuring the quality of temperature-sensitive and delicate products.

Adjustable Speed

You can adjust your speed to control shear and impact on your wet feed, resulting in a more controlled dried product.

Particle Size Control

Altering the plate speed and design as well as the volume of back mix allows you to obtain a wider range of particle sizes. Dried product ranging from a D(50) of 3 µm to small agglomerates are achievable.

All-In-One Operation

The high-speed dispersion can be adjusted to break down particles, producing a consistently sized, dry powder. This provides the capability to combine unit operations typically carried out separately in one unit.

How does it work?

A revolution in drying. The PCX is a unique dispersion drying technology designed to handle highly viscous, non-pumpable materials, transforming them into a fine powder or small granules.

The PCX will accept a feed of any consistency, including free-flowing solids, wet cakes, pastes and slurries. Wet feed is either dropped into the heated inlet air stream or introduced directly into the PCX dryer.

The PCX flash drying system utilizes A direct thermal design, meaning the process material is in direct contact with the heat transfer media. In most cases, this media is heated process air.

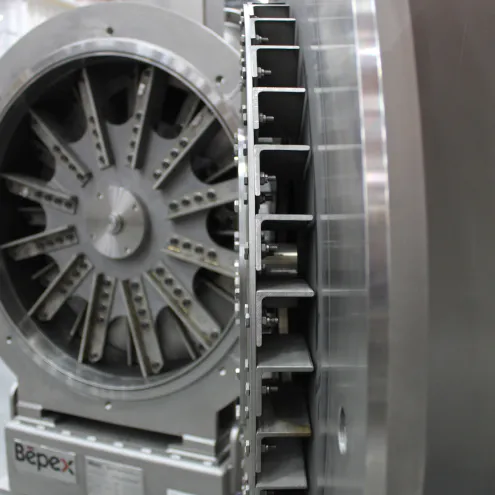

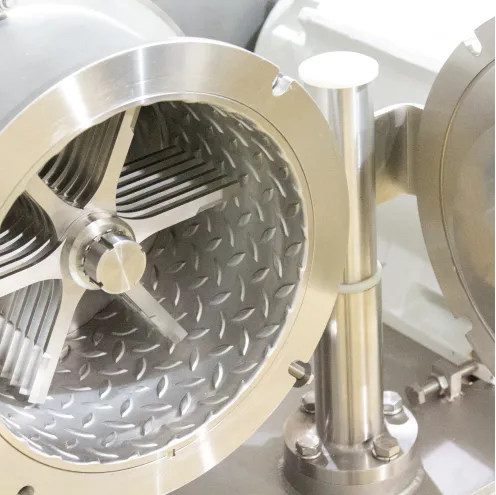

Inside the drying chamber, dispersion plates spread material into a thin layer along the periphery of the machine. Dispersion plate rotation increases solid surface area for rapid heat and mass transfer. This dispersion exposes particle surface area for more efficient drying, while breaking any wet clumps to promote more consistent drying. Rotating dispersion plates also provide intense mixing, removing the need for external back-mixing components.

The solids are in the drying chamber for no more than a few seconds. They are then pneumatically conveyed along with the moisture-laden air to a cyclone or baghouse lter collector. The moisture-laden air provides evaporative cooling for the solids, protecting temperature sensitive materials.

Following the dryer, a classifier or a baghouse filter collector separates the dried product from the process air. In some applications where build-up is a concern, a fraction of the dried product will be recycled back to the PCX to help serve as back mix.

Corn Fermented Proteins

Corn-protein feeds are easily damaged in processing. Traditional drying equipment often damages proteins. Bepex’s proprietary drying technology dries non-pumpable, water-laden solids without excessive heat input. Plus it offers tighter control over product quality while utilizing far less utilities and floorspace.

Learn More

Industrial Starch Manufacturing

Bepex brings scalable, continuous processing to starch production. The Bepex starch processing system provides independent control over mixing, drying, heating, and reaction. That provides operational flexibility while creating superior product with lower production costs — so you can create a wide range of products with consistent, repeatable results.

Learn More

Lithium

Bepex has been supplying processing technology for lithium carbonate or lithium hydroxide production since the early 1990s. Now Bepex is pioneering drying and milling systems to streamline lithium production while reducing the energy needed and emissions resulting from production.

Learn More

Plant Based Proteins

Bepex offers the most energy efficient, cost effective and environmentally friendly systems for processing plant-based production. Bepex systems require less energy and create less emissions. Plus they provide more control over protein modification, resulting in a higher quality product.

Learn More

Pomace

Bepex transforms “waste” pomace into high-value protein products. Bepex offers a total solution to ensure consistent feeds, wring water from the pomace, and dry the wet cakes into powder or small granules. That improves efficiency and product quality, while lowering costs and reducing emissions.

Learn More

Starch Modification

The Bepex food-grade starch processing system offers independent mixing, drying, heating, and reaction processing. Adjustability in residence time, temperature and gas concentration allows for easy modification of color, RVA profile, or other functional requirements. That provides production flexibility while creating a premium product.

Learn More

Yeasts

Bepex is a leader in equipment to recover protein from spent yeasts. Bepex provides superior control over drying, lower operating costs, and high capacity in a compact footprint. The result: better product and better cap ex return than traditional drying technologies.

Learn More

Recycled Battery Materials

Bepex works with recyclers to reclaim lithium and other materials from spent batteries. With the industry’s widest range of drying, devolatilizing and other technologies and decades of lithium processing experience, Bepex is the ideal partner in development of new recycling processes.

Learn MoreBetter flash drying. Only from Bepex.

Reduce emissions, lower costs, protect temperature sensitive materials. All with Bepex’s proprietary PCX technology.

We welcome inquiries at any stage of development. Whether it’s just a far-fetched idea* or a fully fleshed out RFQ, we’d love to discuss your project in more detail.

p.s. we love far-fetched ideas